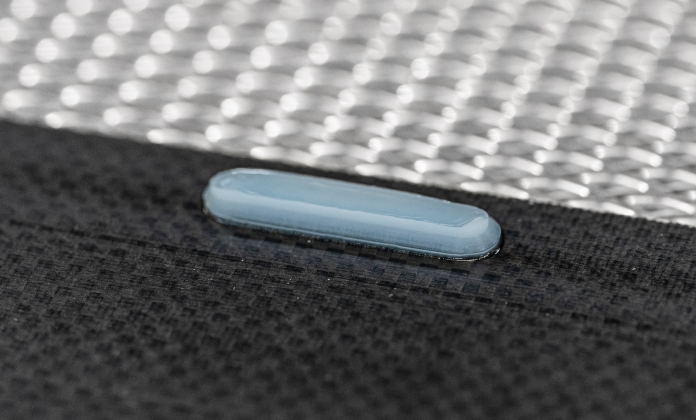

We are replacing conventional metal rivets with innovative resin rivets to meet the increasing requirements for sustainability.

Less energy for production and machining when compared to metal rivets.

Sorted and therefore low-cost disposal of the doctor blade.

Sustainable benefits without forfeiting functionality or a long service life.

Good chemical resistance and water absorption of <2%. Temperature-resistant even in the drying section.

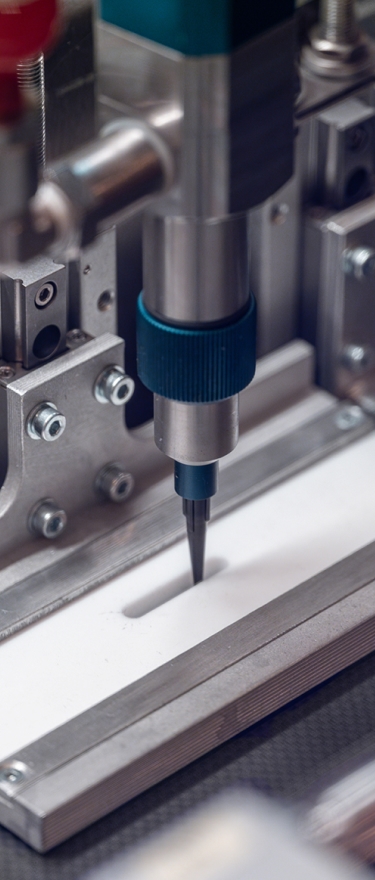

As experts in paper industry and doctor blade production, we have developed our own machine to manufacture resin rivets.

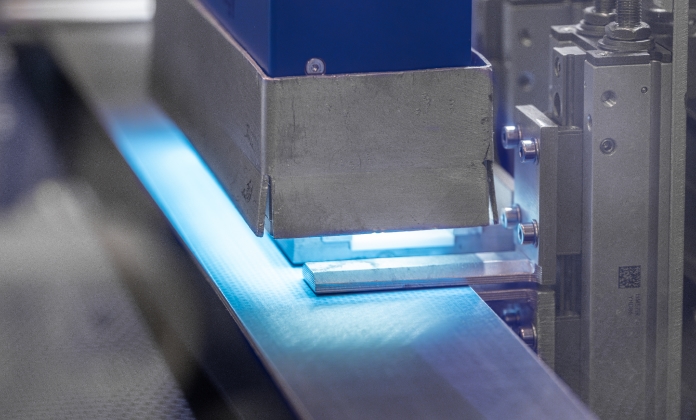

Doctor blade pre-treatments for improved glue adhesion.

Special procedure for precise glue metering so that the quality remains the same.

All-purpose rivet design, compatible with all CLOUTH® holders.

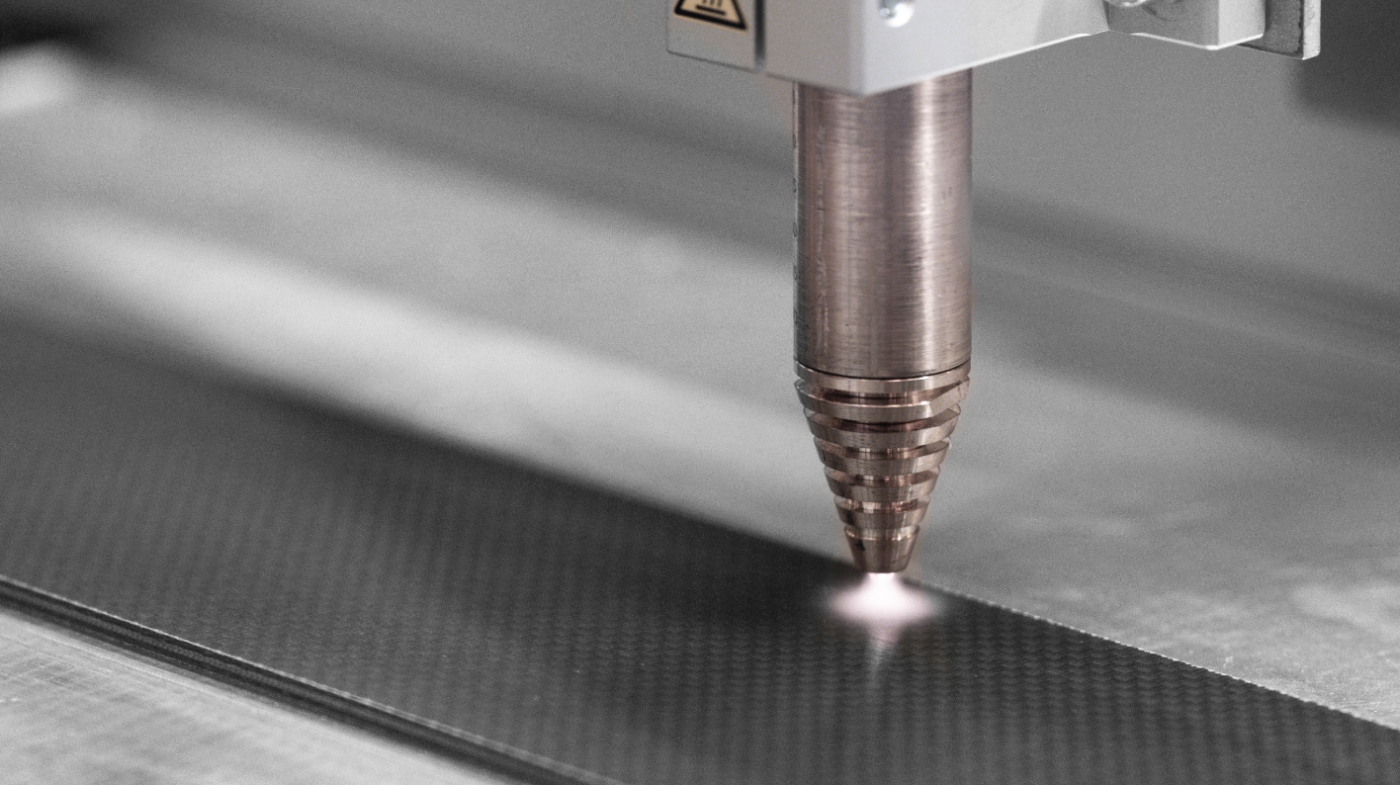

UV hardening technology with drying times of a few seconds.

Get all the key information at a glance! Download our flyer to learn more about resin rivets and their advantages.

Discover our inspiring Footprint Stories and see how innovation and responsibility shape our journey toward a greener future.